Dexpan vs. Concrete Steps

Using Dexpan to Selective Demo a Concrete Step

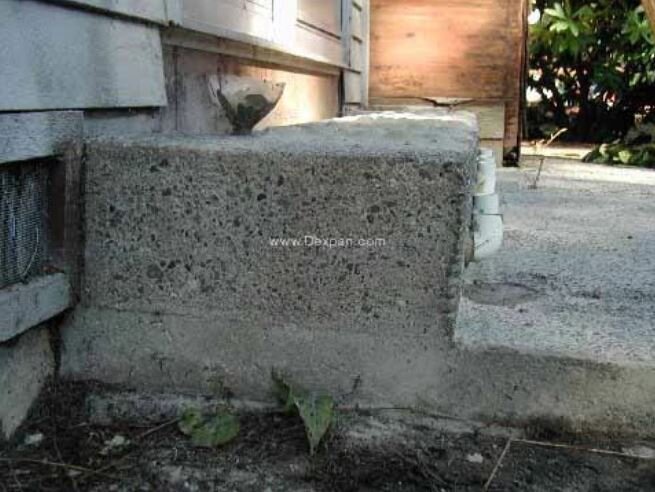

“A house that I purchased for refurbishing had a concrete step poured up against the side of the structure, an open invitation for termites and decay. This is a fairly common error and perhaps others can benefit from my learning process in removal of the step while saving the slab to support a deck with steps. I chose to break the step into usable rectangular blocks for other projects rather than random breaking that only creates rubble that is hard to get rid of.

The 1.5" diameter holes for Dexpan are drilled at a slight angle so that the back end of the hole is about at the surface of the slab. The small holes are 5/8" and drilled nearly to the back edge of the step.

More holes drilled vertically for a break line. The hole with the funnel is 1" diameter, break line holes are 5/8" and do not intersect with the Dexpan holes. Iglued 1" PVC pipe elbow risers into the open end of the Dexpan holes with urethane construction adhesive to provide a riser ensuring that the holes got completely filled with no air pockets.

The step will be replaced with a wooden deck after some minor chipping of the residual humps to allow deck stringers to sit flat. The whole concrete breaking project cost about $120 including Dexpan and drill rental, far cheaper and easier than breaking out with a jackhammer and forming / pouring a new slab. The broken out blocks will be recycled into blocking underneath a garden shed.”

More Customer Job Stories LINK